PRINCIPLES

- This test is performed to determine the consolidated-drained shear strength of a sandy to silty soil.

- The shear strength is one of the most important engineering properties of a soil, because it is required whenever a structure is dependent on the

soil’s shearing resistance.

- The shear strength is needed for engineering situations such as determining the stability of slopes or cuts, finding the bearing capacity for foundations, and calculating the pressure exerted by a soil on a retaining wall.

STANDARD REFERENCE

- ASTM D 3080: Standard Test Method for Direct Shear Test of Soils Under Consolidated Drained Conditions

OBJECTIVES

- To determine the shearing strength of the soil using the direct shear apparatus

- To determine the shear strength of a dry cohesion-less soil

APPARATUS

i) Direct shear machine

ii) Tamper for compacting soil

iii) Auto balance

iv) Drying oven

v) Data acquisition system

PROCEDURE

A) PREPARATION OF SAMPLE

- weigh a large dish of dry sand.

- carefully assemble the shear box and fix into position

- measure the area of the shear box.

- place the sand into the shear box and then place the loading block but make sure the loading block is leveled.

- weight again the container of the sand to determine the weight of material sample.

- obtain the thickness of sample by using the reference line in the loading block.

- apply a normal load of 5kg.(the total vertical load need to include the weight of loading block and the upper half of the shear box)

- separate 2 part of the shear box by advancing the spring screws in the upper half of the shear box.(the space should be slightly larger than the largest grain in the sample)

sample preparation

B) TESTING

- weight the sample then place it into the shear box assemblies.

- go to DS7 Program, select machine - Shearbox.

- select new sample and fill the sample parameter

- initialize all transducers relating to shearbox test (vertical displacement, horizontal displacement and force)

C) CONSOLIDATION STAGE

- initialize all transducers relating to shearbox test (vertical displacement, horizontal displacement and force)

- decide on the Normal Stress to be loaded on the sample.

- load the weights as recommended by the software.

- start count down and check the vertical displacement transducer reading until a constant level reached.

D) SHEARING STAGE

- switch the shearbox machine.

- set the test speed (for example 0.5mm/min)

- start countdown and press the run button on the shearbox machine.

- check the force reading until the force reading reaches the max value and stop the machine when the value has started to drop. Stop stage.

- end all stages. Remove the sample and put it in the oven and determine the dry weight.

- prepare the next sample. Repeat the same procedure.

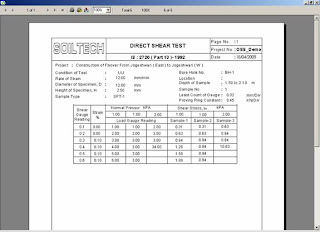

RESULT

- the result will be obtained from the computer.

Example result: